Commissioning in the

Chemical Industry

We are your #1 Resources & Completion System in Chemicals

When it comes to building

chemical industry projects, such as reactors, storage tanks, and other equipment preservation, safety and compliance with regulatory requirements are of the utmost importance. That's where a commissioning and completions system, combined with expert technicians and engineers, comes into play.

A commissioning and completions system provides a systematic approach to verifying that all systems and components of a project are installed correctly and functioning properly. This system ensures that all equipment and systems meet regulatory requirements, such as those set by the Occupational Safety and Health Administration (OSHA) or the Environmental Protection Agency (EPA). It also helps identify and address any issues during construction, reducing the risk of safety incidents, product defects, and costly delays.

Expert technicians and engineers are essential in the construction process. They have the expertise to manage complex construction projects, coordinate multiple subcontractors and vendors, and ensure that all components of the project are integrated and working as intended. They also have extensive knowledge of regulatory compliance and can provide guidance to ensure that the project meets all necessary requirements.

At our complan, we have a team of experienced technicians and engineers who specialize in chemical industry projects. We provide comprehensive services that include planning, design, construction, commissioning, and maintenance. Our team has a proven track record of delivering projects on time and within budget, while ensuring safety and regulatory compliance.

In conclusion, utilizing a

commissioning and completions system, along with our experienced resources, is critical in building chemical industry projects that are safe, efficient, and compliant with relevant regulations. By prioritizing safety and regulatory compliance, we can help your company establish itself as a leader in the industry while delivering high-quality projects that meet the needs of your customers.

Powering innovation through reliable chemistry: Your trusted partner in the chemical industry.

Commissioning and completions are critical to ensure the safe and efficient operation of chemical reactors by verifying that all equipment and systems are installed, tested, and ready for use according to design specifications and regulatory requirements.

With our comprehensive resources and cutting-edge commissioning and completions software, you can efficiently and effectively build reliable and cost-effective solutions for your storage tanks.

WinPCS helps in preserving equipment by providing an effective way to track maintenance schedules, equipment performance, and identify potential issues before they become critical problems, thereby minimizing downtime and extending the lifespan of the equipment.

Chemical Plants & Reactors

Building chemical reactors is a complex process that involves several stages and steps. The first stage is planning, which involves identifying the need for a reactor, selecting the location, obtaining necessary permits, and conducting environmental assessments. The next step is designing the reactor, including determining the size, shape, and selecting appropriate materials. After the design is completed, the construction phase begins, which involves building the structure, installing the necessary equipment and technology, and outfitting the reactor with safety features and controls.

Throughout the construction process, it is critical to use a

commissioning and completions system to ensure that all systems and components of the reactor are installed correctly and functioning properly. This system verifies and documents that all systems meet regulatory requirements, such as those set by the Occupational Safety and Health Administration (OSHA) or Environmental Protection Agency (EPA). It also helps identify and address any issues during construction, reducing the risk of safety incidents, product defects, and costly delays.

Expert technicians and engineers are also essential in the construction process. They can identify potential issues early on, offer solutions, and provide guidance on regulatory compliance. They can also manage and coordinate multiple subcontractors and vendors, ensuring that all components of the reactor are integrated and working as intended.

In summary, utilizing a commissioning and completions system and expert technicians is critical in building chemical reactors that are safe, efficient, and compliant with relevant regulations. By prioritizing safety and regulatory compliance, reactors can operate smoothly and reliably, providing companies with the necessary infrastructure to carry out their operations and deliver high-quality products to their customers.

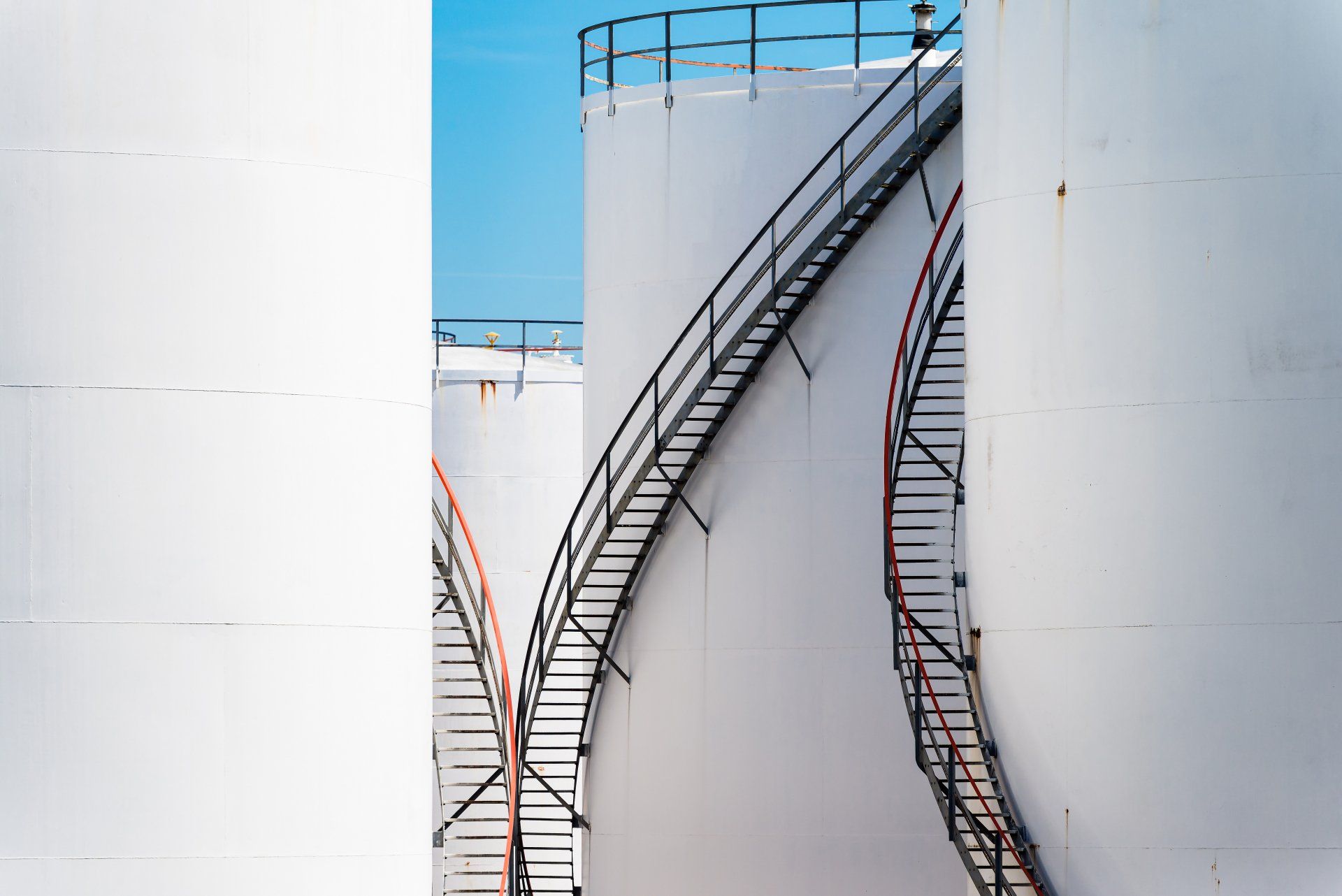

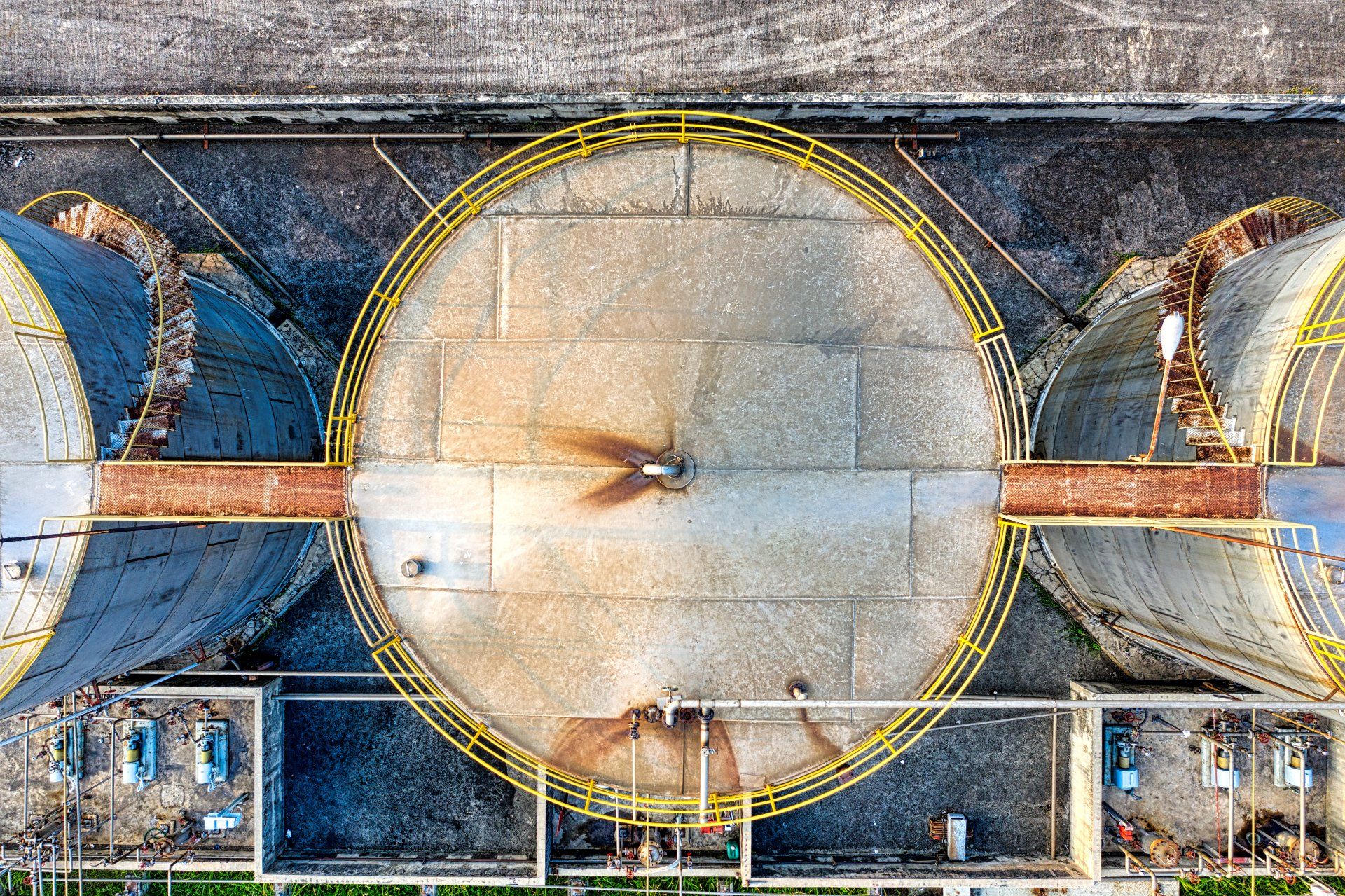

Storage Tanks

Building chemical storage tanks requires careful planning and execution to ensure safety and compliance with regulatory requirements. The first stage is determining the need for storage and selecting the appropriate location for the tank. Once the location is selected, design specifications are created, including the type of tank, materials used, and safety features.

During the construction phase, expert technicians oversee the installation of the tank and ensure that all safety features are properly integrated. This includes ensuring that the tank is level and secure, and that any potential hazards are identified and addressed.

Using a commissioning and completions system is essential in verifying that the tank is installed correctly and functions as intended. This system verifies and documents that all systems meet regulatory requirements, such as those set by the Occupational Safety and Health Administration (OSHA) or Environmental Protection Agency (EPA). It also helps identify and address any issues during construction, reducing the risk of safety incidents, product defects, and costly delays.

Expert technicians play a critical role in the construction process by providing guidance on regulatory compliance and identifying potential issues early on, offering solutions to ensure that the tank operates safely and efficiently. They also ensure that the tank is regularly inspected and maintained, which is essential to preventing leaks and other safety hazards.

In summary, using a

commissioning and completions system and expert technicians is critical in building chemical storage tanks that are safe, efficient, and compliant with relevant regulations. By prioritizing safety and regulatory compliance, tanks can operate smoothly and reliably, providing companies with the necessary infrastructure to carry out their operations and deliver high-quality products to their customers.

Equipment Preservation

Equipment preservation is a critical process in ensuring the safety and reliability of industrial equipment. The first stage is to develop a preservation plan that outlines the necessary actions to preserve the equipment during transportation, storage, and commissioning. This includes identifying any potential hazards, such as corrosion or damage from moisture, and implementing measures to mitigate these risks.

During the preservation process, expert technicians oversee the implementation of the preservation plan, ensuring that all equipment is properly protected and maintained. This may involve applying coatings or inhibitors to prevent corrosion, sealing openings to prevent moisture from entering the equipment, and performing regular inspections to ensure that the equipment is in good condition.

Using a commissioning and completions system is essential in verifying that equipment preservation procedures are properly implemented and meet regulatory requirements. This system helps to ensure that all necessary steps are taken to preserve the equipment and that the equipment functions properly once commissioned.

Expert technicians play a critical role in the preservation process by providing guidance on regulatory compliance and identifying potential issues early on. They also ensure that the equipment is regularly inspected and maintained, which is essential to preventing failures and other safety hazards.

In summary, using a

commissioning and completions system and expert technicians is critical in equipment preservation, ensuring that industrial equipment remains safe, efficient, and compliant with relevant regulations. By prioritizing equipment preservation, companies can protect their investments and minimize the risk of costly failures, downtime, and safety incidents.

Let’s talk about your project

If you are looking for a project management solution that can help you manage your industrial construction project more efficiently, we are here to help.

Contact us today to learn more about our project management solutions, including our flexible team approach and project consultancy services, and how we can provide you with the expertise and resources to achieve project success.

Fill in the form or call to set up a meeting at

(281) 957-5777.